Customer

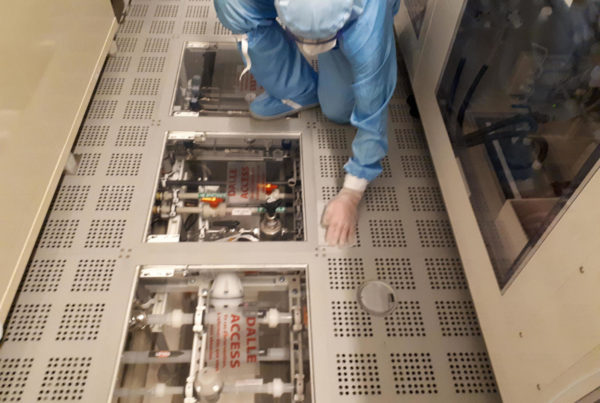

The microelectronics producer used an epitaxy process which consists of depositing in nanometric layers the elements forming an ad hoc crystalline structure. One of the most widely used elements for this technology is arsenic. During the manufacturing process, arsenic contamination spread throughout the process equipment, in production areas (clean rooms, air conditioning) and also in administrative areas.

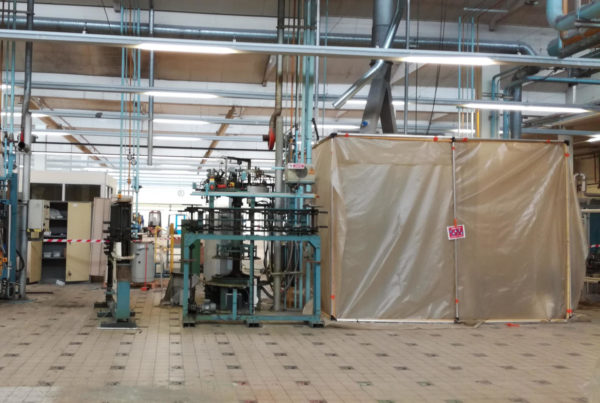

CURIUM carried out the decontamination of clean rooms (2,000 m²), of a storage workshop (300 m²) and of equipment (280 tons) contaminated with arsenic.

CURIUM, jointly with the client, defined a sampling plan and contamination thresholds. A decontamination methodology has been developed based on different surfaces. CURIUM was responsible for the design of the works in clean rooms and in an unbreathable atmosphere (presence of arsine and phosphine) and on equipment containing phosphorus.

The CURIUM team then conditioned the waste for recovery or disposal, and followed up the cross-border movement of the waste.