Customer

A production line had to be dismantled, which had used metallic mercury that was vaporized during the manufacturing process.

Diagnostics were carried out by CURIUM to determine the level of contamination. For this purpose, a control area was defined and secured.

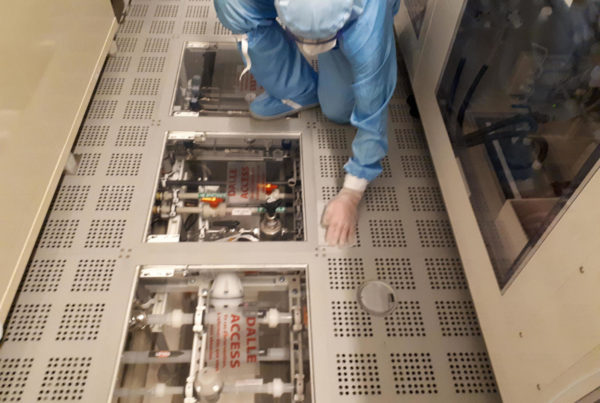

The decontamination works concerned the production line (3 units and conveyors) and the floor around the unit. Each unit and conveyors were placed in containment structures connected to an air extractor with mercury specific activated carbon filtration.